Latest update February 5th, 2026 12:35 AM

Latest News

- Four found dead on vessel at Water Street wharf

- Teixeira says no personal security or vehicle for Opposition Leader

- US says it has returned to Venezuela all $500 million of initial oil sale

- ‘Where Is the Work’ — Mahipaul alleges corruption, demands forensic audit of local govt. projects

- ‘Budget betrays Guyana’s workers’ — WIN MP Singh slams 2026 spending plan, calls out parliamentary disorder

Guyana burdened with US$43M Skeldon factory debt until 2033

May 21, 2017 News

By Kiana Wilburg

Having saddled the nation with billions of dollars in debt, the opposition party has left Guyana with nothing to show for US$200M that was invested in the Skeldon Sugar Factory.

In fact, for the next 16 years, Guyana will be repaying billions of dollars as loans taken for the industrial unit. By that time, the factory will just be another costly reminder of a PPP project that came with great promises and failed to do its job.

This plant was to boost the sugar production figures of the industry; to essentially rescue the sugar sector from its ailing state. Instead, it turned out to be a contributing factor to the poor health of the industry.

According to the Ministry of Finance, the government contracted two loans for the Skeldon project. These were from the Export Import Bank of China, the repayment period for which ends in 2025 and; the Caribbean Development Bank, the repayment period for which ends in 2033.

On the two loans, the total amount that the government is paying (principal and interest) is US$3.8 million per year. The outstanding amount to be paid is US$43,758,818.

While the nation is burdened with these loans for several years, it has no choice but to divest the Skeldon Sugar Factory given the state of affairs that exist. The money made from the divestment of Skeldon is expected to go towards programmes for diversification in the sugar industry as well as to reduce some of the debt garnered over the years by the Guyana Sugar Corporation (GuySuCo).

GuySuCo officials also told Kaieteur News over the weekend that the decision to divest Skeldon is perhaps the best one for the nation.

The officials reminded that since before the decision was taken, Skeldon was simply falling to pieces and it was pointless for government to even invest money to repair it.

This newspaper understands that the deplorable state of the Skeldon Sugar Factory was well documented in a damning audit report. The report also provided numerous telling images of the bagasse-fired power plant within the factory. This was a main area of concern and focus for the international firm that conducted the technical assessment of the factory.

The auditors found that the entire insulation was missing for the plant’s diffuser resulting in major heat losses. The auditors were also left with no choice but to flag the plant’s boiler fuel feeders noting that it posed serious safety issues.

The auditors said, “Frequency converters for bagasse feeder motors were missing and not working due to lack of spares. Further, the conveyer feeder junction box and connection boxes were in a bad condition.”

Discovered as well, was the fact that exhaust gas leakages in the boilers occurred due to wrong furnace pressure. Broiler platforms were also deemed dangerous due to severe extent of corrosion.

The auditors in their investigation of the $200M entity found that oil burners for the boilers were demolished and considered it to be a fire hazard. The auditors are of the firm view that the dreadful condition of the insulators for the boilers was also a health risk for employees there. During their audit, it was found that furnace wall tubes need replacement and superheat tubes were damaged.

The auditors were also alarmed by the fact that the mere lack of spare parts prevented crucial repairs of certain aspects of the factory.

Additionally, the auditors found alarming, the level of corrosion to various parts of the factory and the power plant.

The auditors stressed that the plant is in a very poor and dangerous condition for the operating personnel. They have since informed GuySuCo officials that major equipment damage and accidents can occur at any time, which will result in a severe production loss for the sugar factory and electricity distribution.

The auditors said, “Due to the bad condition of the process and auxiliary equipment, it is not feasible to continue repairing most parts of the plant. Furthermore, the plant operating personnel’s current competence is not adequate to operate and maintain the power plant in a safe and reliable state.”

They added, “There is even no concept for maintenance planning or spare part management. In this regard, there is a general lack of spares and tools at site concerning all areas e.g. mechanical spares, electrical spares, normal hand tools, measuring equipment, safety equipment, etc.”

The infrastructural problems plaguing the US$200M Skeldon Sugar Factory have left some viewing it as a ticking time bomb that will detonate soon; unless tough but necessary decisions are taken.

Chairman of the Guyana Sugar Corporation (GuySuCo), Dr. Clive Thomas, said, “The reality before us is that the factory has lots of faults; it is badly designed and poorly constructed.”

The economist added, “The factory is just not properly built. The cost for the repairs needed is about, if not over US$60M ($12B). It is that big of a disaster.”

Discover more from Kaieteur News

Subscribe to get the latest posts sent to your email.

Similar Articles

Listen to the The Glenn Lall Show

Follow on Tik Tok @Glennlall

Your children are starving, and you giving away their food to an already fat pussycat.

Sports

Feb 05, 2026

BBC Sport – India will play England in the final of the Under-19 World Cup after a record-breaking run-chase against Afghanistan in Harare. The five-time winners chased down an Under-19 World...Features/Columnists

Feb 05, 2026

(Kaieteur News) – Special Economic Zones (SEZs) occupy a curious place in the modern development canon. They are often presented as compact spaces where infrastructure is concentrated, and where growth can be jump-started by design. The promise is alluring. The evidence, however, is sobering....Sir. Ronald Sanders

Feb 01, 2026

By Sir Ronald Sanders (Kaieteur News) – When the door to migration narrows, the long-standing mismatch between education and economic absorption is no longer abstract; a country’s true immigration policy becomes domestic — how many jobs it can create, and how quickly it can match people to...The GHK Lall Column

Feb 05, 2026

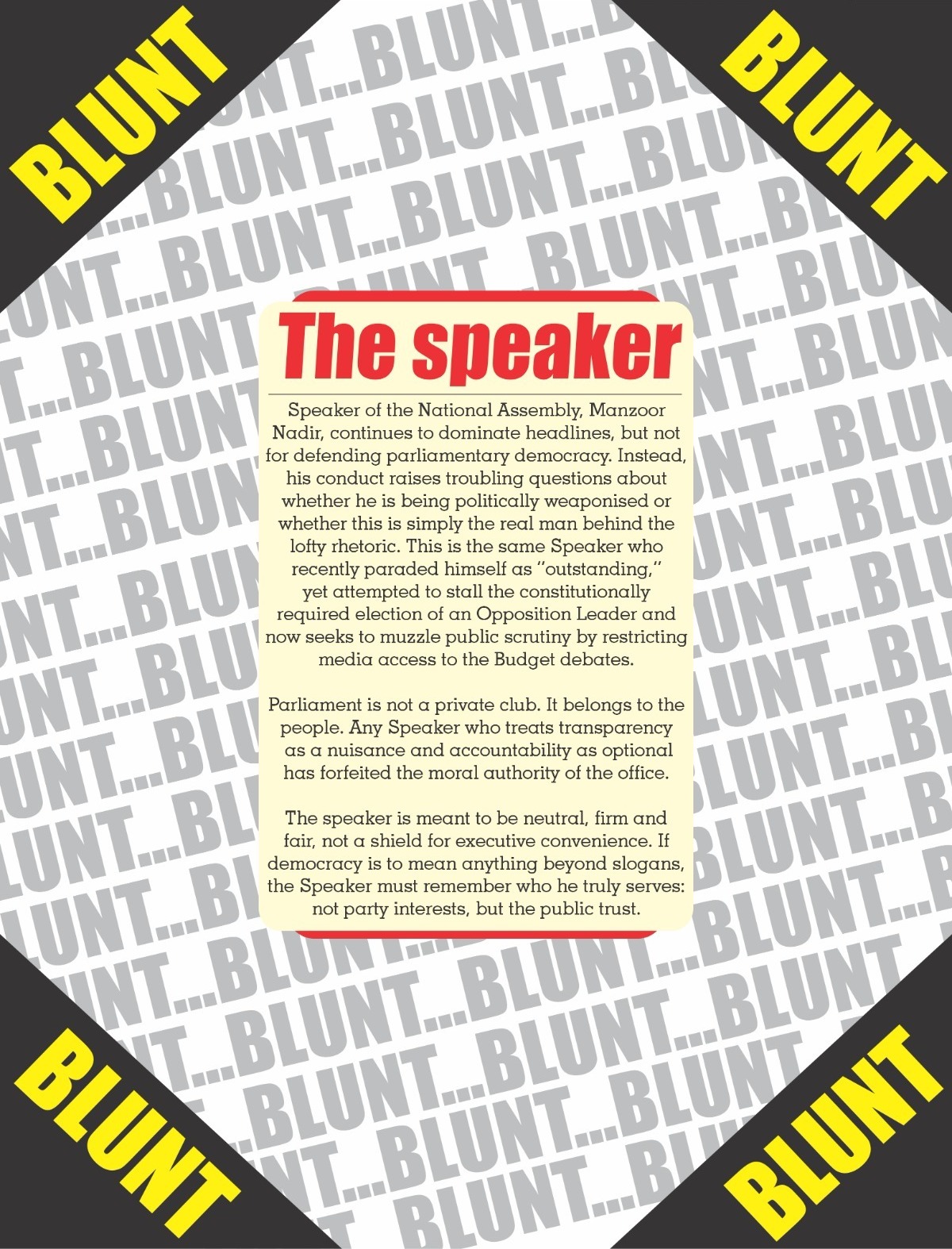

(Kaieteur News) – From all indications, Speaker Nadir is waging a relentless undeclared war against democracy in Guyana. Undeclared, but still unnerving, undermining of wat’s held sacred. Parliamentary democracy. Democracy’s ideals. Democracy’s routines. The selection of the...Publisher’s Note

Freedom of speech is our core value at Kaieteur News. If the letter/e-mail you sent was not published, and you believe that its contents were not libellous, let us know, please contact us by phone or email.

Feel free to send us your comments and/or criticisms.

Contact: 624-6456; 225-8452; 225-8458; 225-8463; 225-8465; 225-8473 or 225-8491.

Or by Email: glennlall2000@gmail.com / kaieteurnews@yahoo.com